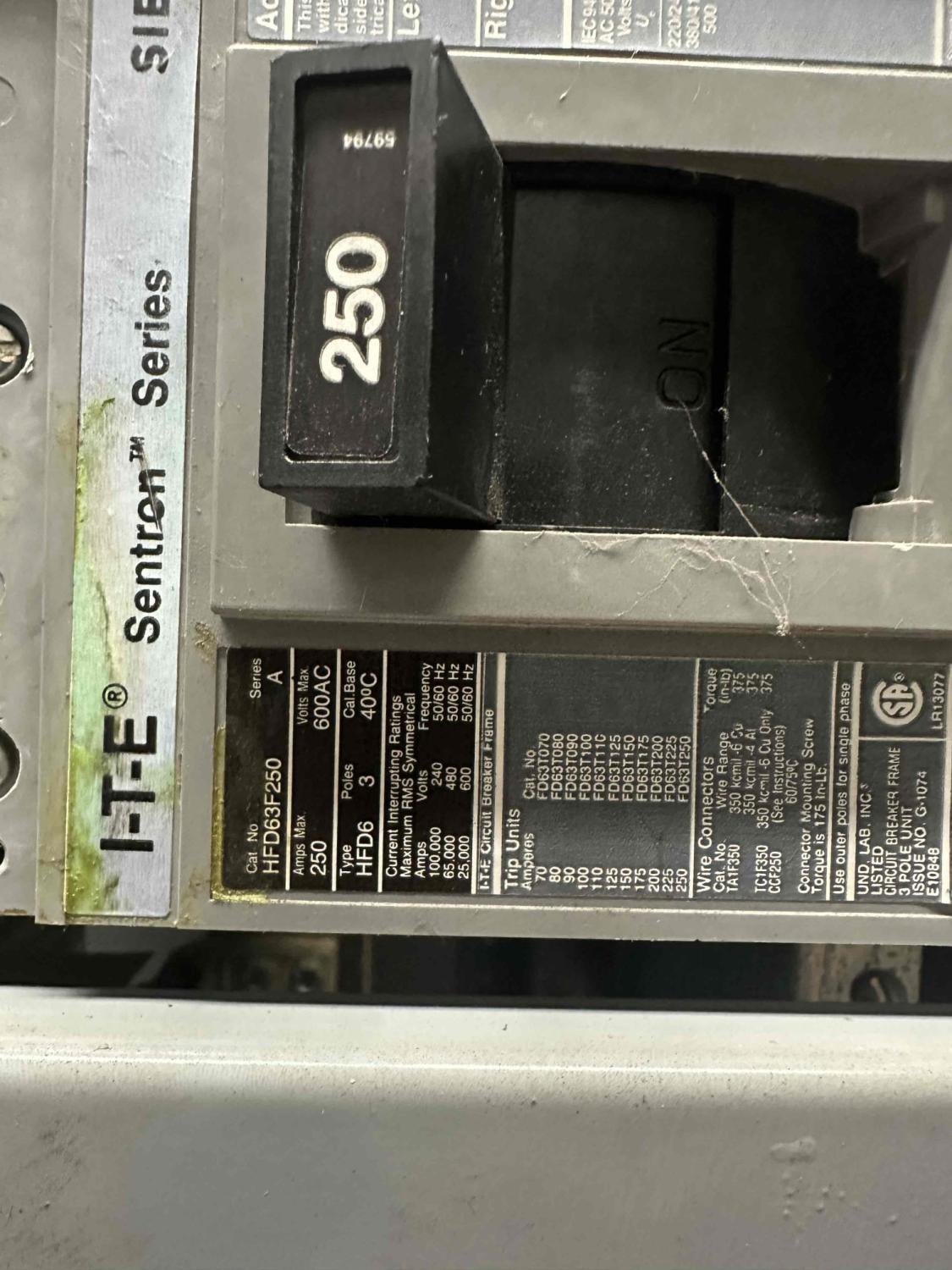

PROJECT DESCRIPTION: EMERGENCY MAIN BREAKER REPAIR WITH TEMPORARY BYPASS – FORT MYERS, FL

We recently completed an emergency service call at a commercial office in Fort Myers, FL 33901, where the 250-amp main breaker had been tripping overnight for two days straight. This issue left the front office without power and required immediate attention.

WHAT WE DID:

- Met with the on-site team to review power loss in the front office

- Inspected the main distribution panel (MDP) and found abnormal heat on the A phase

- Detected temperatures up to 216°F using a temperature gun—even though the circuit was pulling only 9 amps

- Determined the breaker was internally failing and not caused by overloaded circuits

- Performed a temporary repair using Polaris taps and safely landed the conductors on a different breaker

- Torqued all connections, including Polaris taps and breaker lugs, to manufacturer specifications

- Verified system performance with voltage and amperage testing

- Conducted follow-up infrared imaging after one hour to confirm the issue was resolved

THE RESULT:

The electrical issue was isolated, power was restored, and business operations resumed without further disruption. This temporary solution will remain in place until the new MDP arrives and we perform a panel replacement.

If you’re dealing with flickering lights, hot panels, or breakers that trip unexpectedly, visit our Commercial Electrical Troubleshooting page to learn how we can help.

FREQUENTLY ASKED QUESTIONS

What caused the breaker to fail?

Although the load was light, the breaker was overheating internally. This is often due to mechanical fatigue or corrosion within the breaker, not a wiring issue.

Was this a permanent fix?

No. This was a temporary but safe bypass using Polaris taps. We’ll return to install a new panel as soon as it’s delivered. Learn more about our panel upgrade services.

Is bypassing a breaker safe?

When done correctly, yes. All components were torqued to spec and verified using thermal imaging. Our team follows NEC code and uses high-quality materials like Polaris taps.

How do you confirm it’s not the wire?

We used an infrared camera to check conductor temps after rerouting. Readings were normal, proving the problem was with the breaker, not the wire itself. You can read more about this process on our Electrical Inspection page.

How long did this take?

Start to finish, the job—including diagnosis, rerouting, and thermal testing—took under 3 hours. Fast response and efficient troubleshooting made the difference.

Gallery