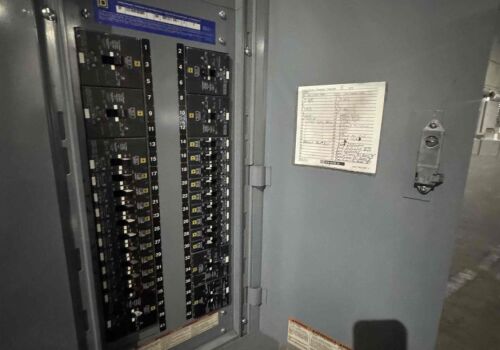

PROJECT DESCRIPTION: FORKLIFT DISCONNECT ESTIMATE – FORT MYERS, FL

Coharbor Electric was recently contacted in Fort Myers, FL 33905 to provide an estimate for installing a dedicated electrical disconnect to support forklift operations. Heavy-duty equipment like forklifts requires safe and reliable power handling, and a disconnect ensures both safety and compliance with electrical codes.

WHAT WE PROPOSED:

- Supply and install a properly sized disconnect rated for forklift power requirements

- Ensure installation complies with NEC standards for heavy equipment disconnects

- Mount disconnect in an accessible location for operators and maintenance staff

- Use appropriate conduit and wire sizing based on forklift electrical load

- Label and document the disconnect clearly for future reference and inspections

- Provide grounding to ensure equipment and personnel safety

THE RESULT (EXPECTED):

With this installation, the forklift will have a dedicated disconnect that provides quick shutoff in case of maintenance or emergencies. This protects both personnel and equipment while ensuring compliance with OSHA and NEC safety requirements.

FREQUENTLY ASKED QUESTIONS

Why does a forklift need a disconnect?

A disconnect allows operators or maintenance staff to safely isolate the forklift’s electrical supply during service or emergencies.

What size disconnect is required?

The rating depends on the forklift’s electrical demand. Our team will size the disconnect based on the manufacturer’s specifications.

Where will the disconnect be installed?

Typically, it will be mounted near the charging or operating station for quick access.

How long does installation take?

Most forklift disconnect installations can be completed within a few hours once materials are confirmed.

Is this OSHA and NEC compliant?

Yes, we size and install all equipment to meet OSHA safety regulations and the National Electrical Code.

Gallery